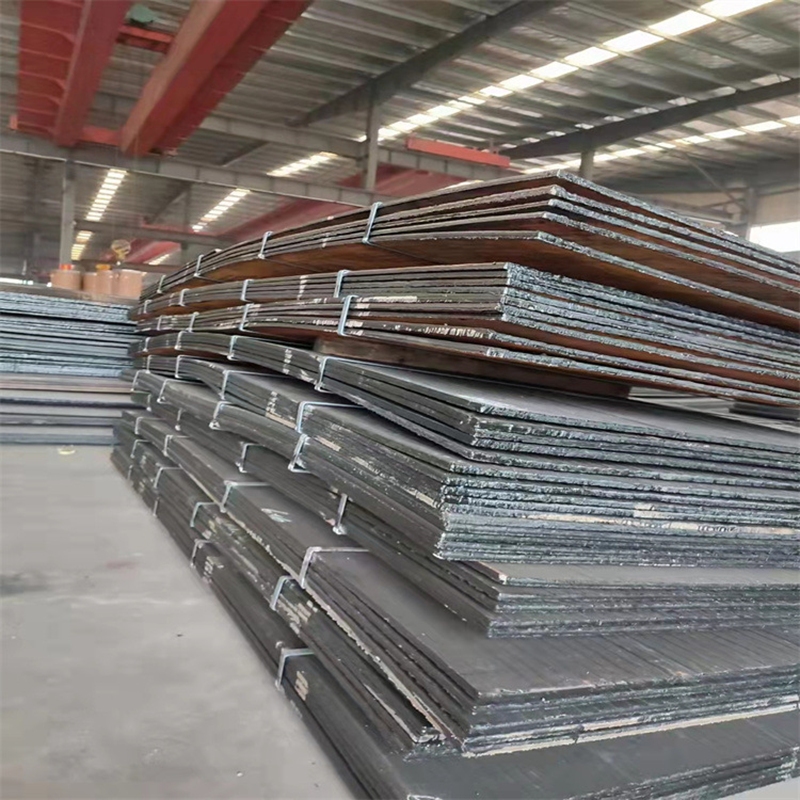

1. Kwambara isahani idashobora kwihanganira

Kwambara isahani irwanya ibyuma, aribyo isahani idashobora kwangirika, ni ibicuruzwa bidasanzwe bikoreshwa cyane cyane ahantu hanini ho kwambara. Igizwe na plaque ya karubone nkeya hamwe na alloy idashobora kwihanganira.

Isahani idashobora kwangirika ifite ibiranga imbaraga nyinshi kandi birwanya kwambara cyane. Umuti wihanganira kwambara muri rusange ni 1/3 kugeza 1/2 cyubugari bwuzuye. Iyo mukazi, matrix itanga ibintu byuzuye nkimbaraga, ubukana hamwe na plastike kugirango irwanye imbaraga ziva hanze, kandi igipande kidashobora kwihanganira kwambara gitanga kwambara kugirango cyuzuze ibisabwa kugirango akazi gakorwe.

Hariho ubwoko bwinshi bwibyuma bidashobora kwangirika, harimo ibyuma bidashobora kwangirika kwambara hamwe nibyuma bizimya ibyuma bidashobora kwangirika. Kurugero, isahani ya KN60 idashobora kwangirika nubwoko bwibicuruzwa bikozwe muguhuza umubyimba runaka wurwego rwimyenda idashobora kwihanganira hamwe nuburemere bukomeye hamwe no kwihanganira kwambara neza hejuru yicyuma gisanzwe cya karuboni nkeya cyangwa ibyuma bito cyane hamwe nuburemere bukomeye na plastike binyuze muburyo bwo kugaragara. Ibipimo bya tekinike ya KN60 isahani idashobora kwangirika ni ibi bikurikira: ubukana bwa Vickers ni 1700HV; ibikoresho ni ibyuma bya karuboni nkeya, nubundi bwoko bwa surfacing hard alloys na niobium karbide birashobora gutangwa ukurikije ibisabwa. Chromium na boron alloy karbide irakungahaye; ubukana bwurwego rwimyenda irwanya ni C62-65 HRc; umubyimba ni milimetero 3 - 15; ibikomeye bivanze birenze 50%; ubushyuhe ntarengwa bwo gukora ni 1000 ° C.

Byongeye kandi, isahani idashobora kwambara isahani 360 nayo ni ubwoko bwimbaraga nyinshi kandi zidashobora kwambara cyane. Yakozwe nubuhanga bwicyubahiro kandi ifite imbaraga zingutu nimbaraga zo gukomeretsa, hamwe no kurwanya kwambara neza no kurwanya ingaruka.

2. Gukoresha ibyuma bidashobora kwambara

2.1 Urwego runini rwibikorwa byinganda

Ibyuma bidashobora kwambara ibyuma bisanga ibintu byinshi mubikorwa bitandukanye. Mu nganda zibyuma, zikoreshwa mubikoresho nka crusher hamwe n'umukandara wa convoyeur, bihora bikorerwa abrasion n'ingaruka. Mu nganda z’amakara, bakoreshwa mu makara y’amakara n’imashini zicukura amabuye y'agaciro kugira ngo bahangane n’imiterere mibi yo kwambara. Inganda za sima zikoresha ibyuma bidashobora kwangirika mu itanura no gusya kugirango ubeho igihe kirekire. Mu nganda z’amashanyarazi, zikoreshwa muri pulverizeri yamakara hamwe na sisitemu yo gutunganya ivu.

Kurugero, isahani idashobora kwangirika isahani 360 ikoreshwa cyane mubice nk'imodoka, gari ya moshi, indege, metallurgie, inganda z’imiti, imashini, peteroli, amashanyarazi, kubungabunga amazi, no kubaka. Nibyiza kubice bitwara ibintu byinshi mumashini yinganda kubera kwihanganira kwambara neza, kurwanya ingaruka, no kurwanya ruswa.

2.2

Ugereranije nibindi bikoresho, ibyuma birwanya kwambara ibyuma bitanga igiciro kinini. Nubwo igiciro cyambere cyibyuma bidashobora kwangirika bishobora kuba hejuru gato ugereranije nibikoresho bimwe na bimwe gakondo, birwanya kwambara kwinshi kandi biramba bivamo kuzigama cyane mugihe kirekire. Kurugero, isosiyete ikoresha ibyuma bidashobora kwangirika mubyuma byayo mubikorwa byayo irashobora kugabanya igihe gito cyo gufata neza ibikoresho no kuyisimbuza, bigatuma umusaruro wiyongera no kuzigama.

Dukurikije amakuru, ubuzima bwa serivisi bwibyuma bidashobora kwangirika akenshi buba bwikubye inshuro nyinshi ugereranije nibyuma bisanzwe. Ibi bivuze ko ibigo bishobora kugabanya amafaranga yibikoresho hamwe nogukoresha igihe. Byongeye kandi, imikorere myiza yicyuma idashobora kwambara igabanya ibyago byo kunanirwa ibikoresho no gutinda kwumusaruro, bikarushaho kuzamura inyungu zubukungu. Nkigisubizo, inganda ninshi nizindi nganda zerekana icyifuzo cyibyuma bidashobora kwambara.

3. Gutondekanya ibikoresho byibyuma bidashobora kwambara

3.1 Ubwoko bwibintu bisanzwe

Ibyuma bidashobora kwambara byuma bikozwe muburyo busanzwe bugaragara hejuru yimyenda isanzwe idashobora kwangirika hejuru yicyuma gisanzwe cya karuboni nkeya cyangwa ibyuma bito. Hariho kandi ibyuma bidashobora kwangirika byuma hamwe nibyuma bizimya ibyuma bidashobora kwangirika. Kurugero, icyuma gishobora kwangirika kwambara icyuma gikozwe muguhuza umubyimba runaka wurwego rwimyenda idashobora kwangirika hamwe nuburemere bukomeye hamwe no kwambara neza kuricyuma.

3.2Ubwoko butandukanye buranga

Hariho ubwoko butatu bwibyuma bidashobora kwangirika: ubwoko rusange-bugamije, ubwoko bwihanganira ingaruka, nubwoko bwubushyuhe bwo hejuru.

Icyuma-rusange-cyuma-kirinda ibyuma gifite imikorere ihamye kandi irakwiriye kumyambarire rusange. Ifite imyambarire myiza yo kwambara nimbaraga ziciriritse. Ibikoresho bya tekiniki bishobora kuba birimo urwego rukomeye, mubisanzwe hafi 50-60 HRC. Ibigize ibintu bisanzwe birimo ibintu nka chromium na manganese kugirango byongere imbaraga zo kwambara. Mu mikorere, irashobora kwihanganira urwego runaka rwo gukuramo kandi ikoreshwa cyane mu nganda nko gukora imashini.

Isahani idashobora kwihanganira kwambara ibyuma byashizweho kugirango ihangane n'ingaruka zikomeye. Ifite ubukana buhanitse kandi irwanya ingaruka nziza. Ibikoresho akenshi birimo ibintu bivangavanze byongera ingaruka zabyo. Kurugero, bimwe mubyuma bidashobora kwihanganira kwambara ibyuma birashobora kwihanganira hafi 45-55 HRC ariko bifite imbaraga zo guhangana ningaruka. Ubu bwoko burakwiriye gukoreshwa aho ibikoresho bigira ingaruka kenshi, nko mubucukuzi bwamabuye y'agaciro nubwubatsi.

Isahani yicyuma irwanya ubushyuhe irashobora kwihanganira ubushyuhe bwinshi. Ikozwe mubikoresho bidasanzwe bivangwa bishobora gukomeza gutuza mubushyuhe bwinshi. Ibipimo bya tekiniki bishobora kuba birimo ubushyuhe ntarengwa bwo gukora bugera kuri 800-1200 ° C. Ibikoresho bigize ibintu bisanzwe birimo ibintu nka nikel na chromium kugirango harebwe ubushyuhe bwo hejuru. Mu mikorere, ikoreshwa cyane mubushuhe bwo hejuru nk'itanura n'amatanura mu nganda za metallurgji na sima.

Igihe cyo kohereza: Ukwakira-31-2024